Products for Cement Industry

Products for Cement Industry

NTN products are available that can provide a long service life under dust, high-load and high-temperature environments, which contributes to reductions in maintenance costs.

Cement Bearings

Improve your performance by Incredible durability and performance.

NTN bearings are designed for the cement industry: NTN Quality Assurance

In the cement industry, from the raw material grinding stage to the finished cement production process, the requirements for bearing durability and performance are extremely high.

NTN has introduced a series of bearings specially designed for mills, clinker kilns, cooling fans and gearboxes. These products not only meet but also surpass conventional standards thanks to the advanced technology and techniques applied by NTN in the manufacturing process.

The benefits of long-standing experience

A Leader in Asia and Japan, NTN has a presence on many production sites throughout the world. We have earned our status thanks to the development of bearings adapted to the requirements imposed by temperature, dust and heavy loads. Our bearings also provide the reliability and durability of the equipment of our end-users.

Incredible durability and performance

NTN focuses on improving durability and performance through many innovations:

- Optimized cage design enhances strength, especially important in applications such as vertical mills.

- Higher load capacity is achieved thanks to special heat treatment processes such as carburizing, carbo nitriding, which increase hardness and wear resistance.

- Increase high-speed performance with the SRB ULTAGE series, delivering superior operating performance to your equipment.

Outstanding efficiency and benefits

NTN focuses not only on durability and performance but also on efficiency and benefits:

- Total cost of ownership ( TCO) savings : Reducing maintenance time and increasing usage time helps save significant costs for businesses.

- Smaller bearings are suitable for operating conditions, saving space and costs for manufacturers.

- Reduce environmental impact by reducing energy consumption, while also reducing CO2 emissions.

Commonly used product lines

NTN offers a wide range of bearing product lines suitable for different applications, including:

- NTN ULTAGE® Spherical Roller Bearings:These are used flexibly according to conditions and locations of use. “WA type” is used for conveyor belts operating in environments prone to contamination, “EMA type” is used for crushers and vibrating screens serving the mining and processing of raw materials.

- Ball bearings with cover used to seal the cluster and ball bearings with 3-lip rubber seal: These are used in environments prone to contamination.

- Synchronous shaft (CVJ): It supports the transmission of rotational power from the main shaft to the drive shaft without having to place them on the same plane.

- Grease product:There are also grease and automatic grease devices, supporting lubrication in special, hard-to-reach locations.

By continuously innovating technology, NTN not only provides high-quality products but also brings growth value to customers through optimizing performance and minimizing operating costs. This affirms NTN’s position and reputation in the global bearing market, and contributes to the sustainable development of heavy industries.

Applications

- Conveyor Belt

- Crusher

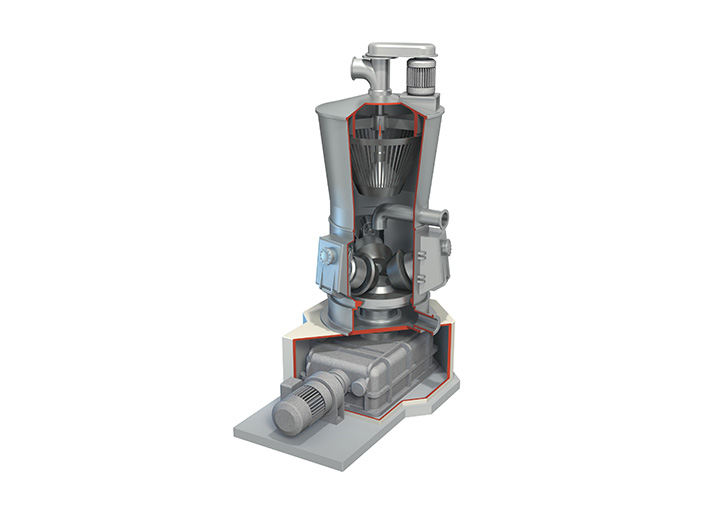

- Vertical Roller Mill Coal Pulverizers

- Bucket Elevator

- Rotary Kilns

- Vibrating Screens

- Ball Mills

- Cooling Fans

- Gearboxes