Product By Category

Bearing

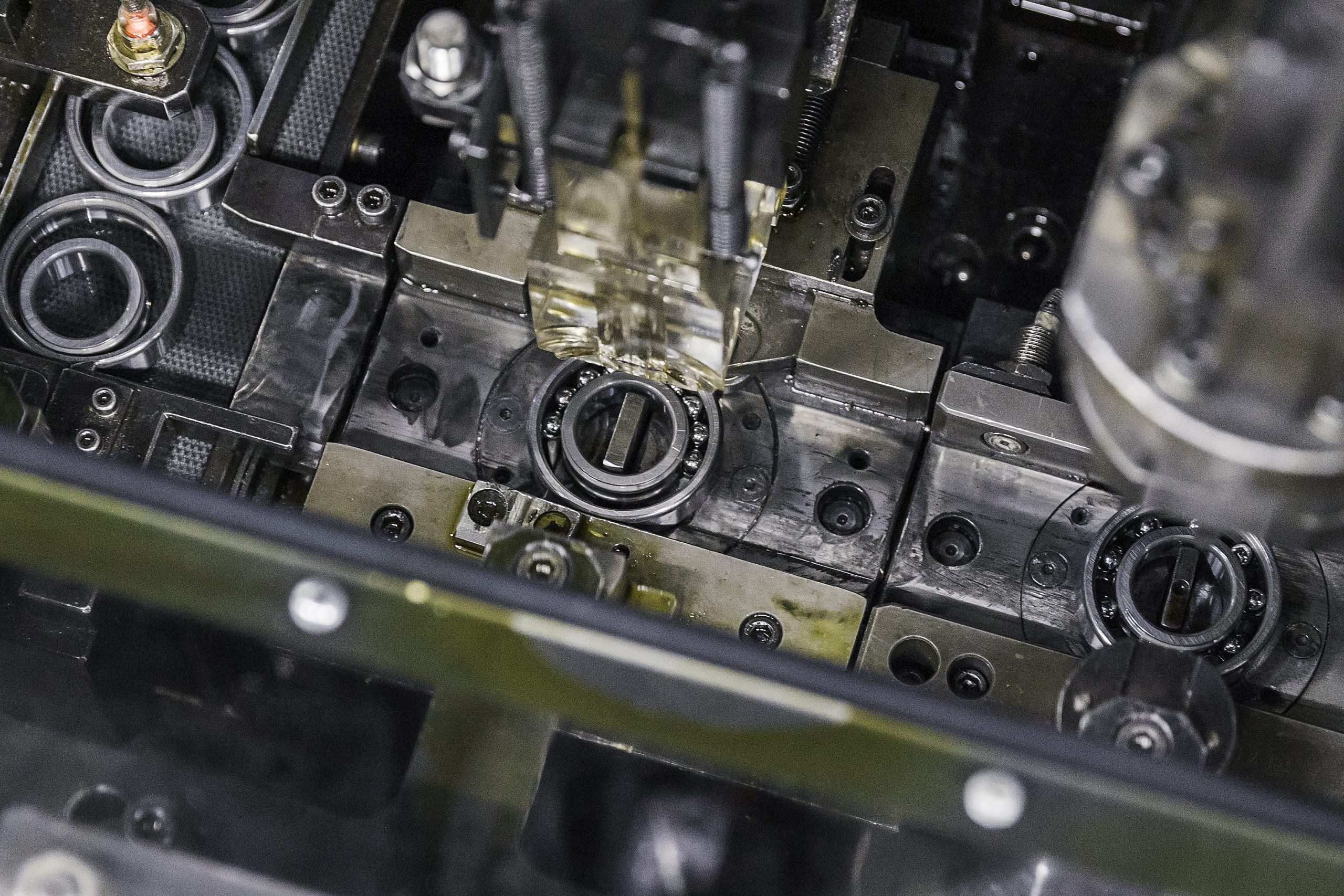

A rolling bearing is a type of bearing that carries loads by means of rollers (balls or rods) between two bearing rings (races). The relative motion of the two bearing rings allows the rollers to move with very little sliding friction and rolling friction.

The structure of a normal rolling bearing consists of four main parts: inner ring, outer ring, balls (or rollers), and spacer (surrounding and maintaining the distance between the rolling balls). The inner and outer rings usually have grooves for the balls or rollers to run. The inner ring is mounted on the shaft collar, the outer ring is mounted on the shaft seat (machine housing, machine body). Normally, only the inner ring rotates with the shaft due to contact through the shaft collar, while the outer ring remains stationary. However, there are also some designs with the outer ring rotating with the shaft seat while the inner ring remains stationary with the shaft (as in the roller bearing of a car wheel).

Ball Bearings

- Radial Ball Bearings